Sales Hot-line: +86-189 0627 1888 Contact Person: Mr.Hu Fax: +86-513-8844 8088

1. Brief introduction

MF raw material homogenizing silo uses the distributor with six slides radiantly and the material can be disposed into the silo to form a horizontal level of material layer. The bottom of silo is subulate shape, slightly oblique to the centre. There is a central mixing chamber in the centre. The bottom of silo between the central silo and silo wall is divided into 6-14 aerating areas and every area has three aerating air slides and one discharge hole. When discharging, aerating works in turn in two opposite areas. There are many sunken funnels in a line among the diameter in discharging point, rotating their angles with changing of the air. In this way, it will not only have a mixture from gravity but also a further homogenization for

raw materials with continuous aerating from the bottom of central room. Because the homogenizing principle of this kind of silo based on material flow gravity mixing in funnel, the consumption of electric power is low. Energy consumption is only 0.432-0.576 kwh / t and homogenizing value is up to 7-10 that show a highly efficient energy-saving, low investment in infrastructure, simple operation and management and so on.

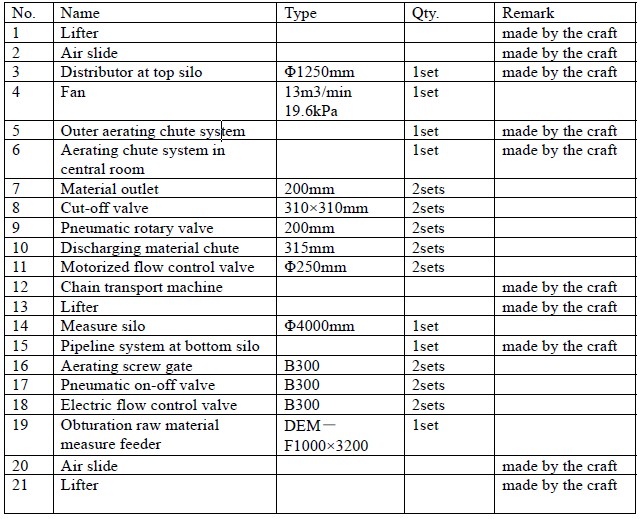

2. Parameter list